Welcome to our websites!

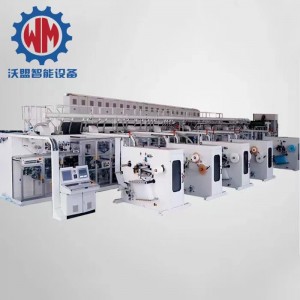

Automatic Pull Up Pants Baby Diaper Making Machine Production

Automatic Pull Up Pants Baby Diaper Making Machine Production、

Products Description

The baby diaper production line includes mainframe, Gluing machine, packaging system and other supporting equipment, including air compressor, visual inspection system and metal detector.

|

Product Name

|

Baby / adult diaper making machine

|

|

Designed Production Speed

|

600 Pieces/Min

|

|

Stable Production Speed

|

500 Pieces/Min

|

|

Material

|

100% Polypropylene

|

|

Use

|

Baby diapers, Adult incontinence

|

|

Machine Voltage

|

380V, 50Hz, Three-Phase Five-Wire

|

|

Machine Power

|

350Kw~400Kw

|

|

Colors

|

Any color available

|

|

Width

|

According to your requirement

|

|

Payment

|

T/T, Alibaba Pay

|

|

Sample

|

Free

|

|

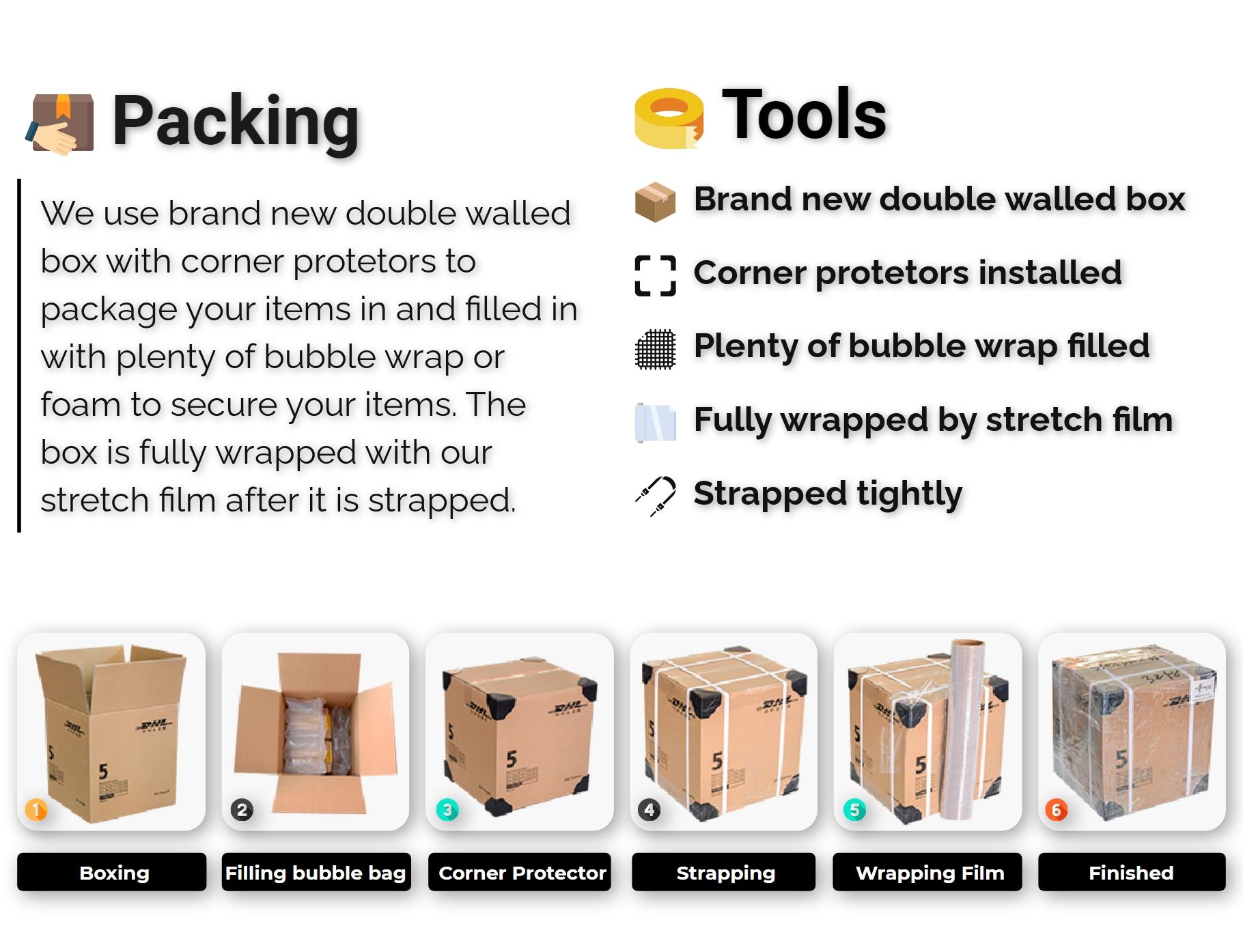

Packaged

|

PP bag+PE wrapping film, According to your requirement

|

|

Machine Size

|

30*7*3.5m(L*W*H) (Can Be Customized)

|

|

Machine Weight

|

50T

|

|

I shape baby diaper production

|

|

|

Overall Size

|

30*6*4m

|

|

Machine Size

|

22*2*3.5m

|

|

Design Speed

|

600pcs/min

|

|

Stable work speed

|

450-500pcs/min

|

|

Pass percentage

|

98%

|

|

Power source

|

380V,50HZ

|

|

Machine capacity

|

about 260kw

|

|

Air pressure

|

0.6-0.8Mpa

|

|

Machine weight

|

About 60T

|

|

Configuration

|

|

|

Product size

|

S: 390×280 M: 450×320 L: 500×320 XL: 525×330

|

|

Safety system

|

It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer.

|

|

Control system

|

PLC control system,Operating on the touch screen,Configure HDTV monitor

|

|

Materials corrective system

|

Germany BST automatic web guide system (optional).

|

|

Drive system

|

Three-axis or full servo

|

|

Product structure

|

Up&Down Tissue, Fluff core(mix with SAP), ADL, Backsheet, Front tape, Topsheet, Leg cuff N.W., Side Tape, Waistband.

|

|

Tension system

|

Up&Down Tissue ADL, Back sheet, Top sheet, Cuff N. W., are adopt A&B shaft active unwinding by inverter motor.

|

|

Packing Way

|

Equipped with the stacker at the request of client.

|

Write your message here and send it to us