Best Price for Sanitary Napkin Production Machine - WM-WSJ600 Full servo sanitary napkin production line – Womeng

Best Price for Sanitary Napkin Production Machine - WM-WSJ600 Full servo sanitary napkin production line – Womeng Detail:

Configuration

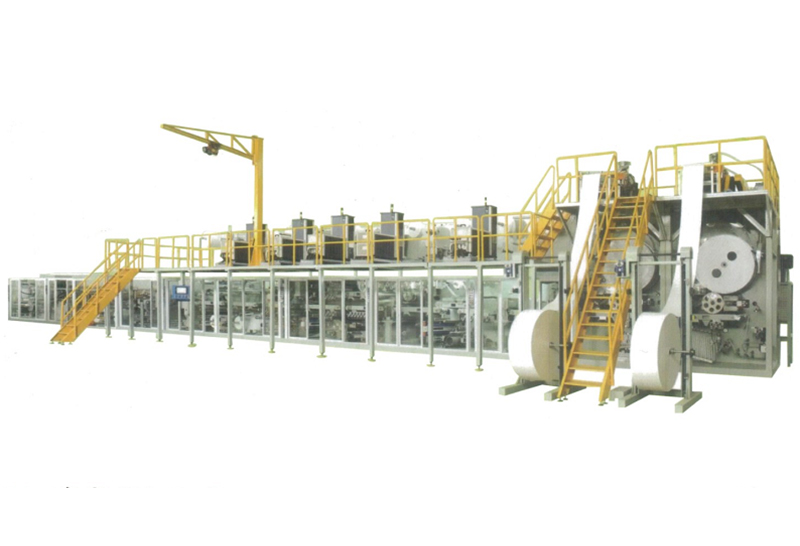

Product structure: cotton pulp macromolecule wrapped in lower toilet paper,surface layer,bottom film,middle paper,small film and wrapped wing paper.

Produce size: 240-350mm( Customized according to customer requirement)

Control system: PLC programming control, HMl operation, LED digital display graphic digitization control.

Tension system: Equipped with tension uncoiling system, constant tension control and storage mechanism, material deviation correction system. This set of constant tension system ensures the stability of material receiving at full speed, minimizes the impact of material tension and reduces the number of shutdown

Drive system: full servo drive, digital size change, ensure run synchronized at full process, The frontal tape adopt servo positioningcutting to ensure pattern consistent with the phase.

Safety system: safety guard installed at the operating side, equipped with emergency stop switch, security identifier. Driven side is equipped with safety pull wire. High audio fan uses sound insulation or silencer.

Packaging system: auto stacker to be defined by customer need (dual push dual exit).

Materials corrective system: Adopt international famous brand deviation correction system

Purchase little knowledge

When purchasing sanitary napkin production equipment, customers should not only pay attention to the appearance characteristics of the machine, but should consider its product quality. Good sanitary napkin production equipment has fast operation speed, long service life, stability and safety. Features such as good performance and strong operability. Therefore, when purchasing sanitary napkin production equipment, you should generally grasp: the operating speed, service life, stability, safety, and ease of operation of sanitary napkin manufacturing equipment.

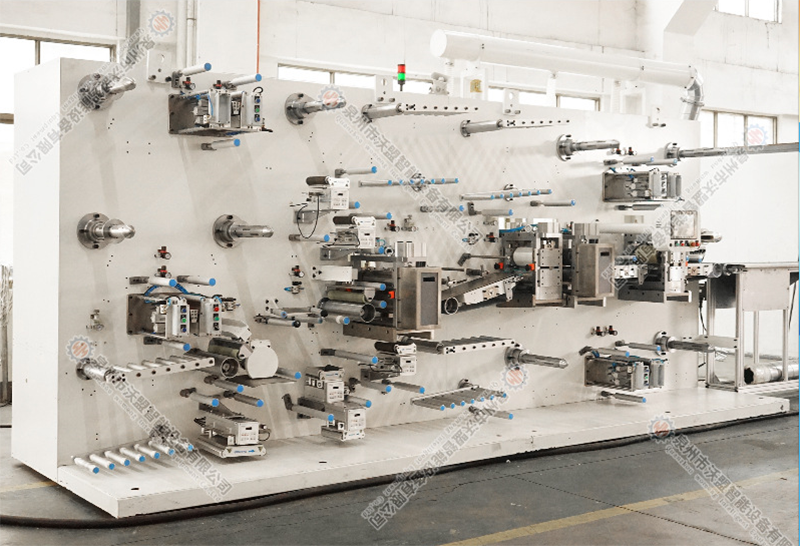

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for Best Price for Sanitary Napkin Production Machine - WM-WSJ600 Full servo sanitary napkin production line – Womeng , The product will supply to all over the world, such as: United States, Greece, Brunei, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!