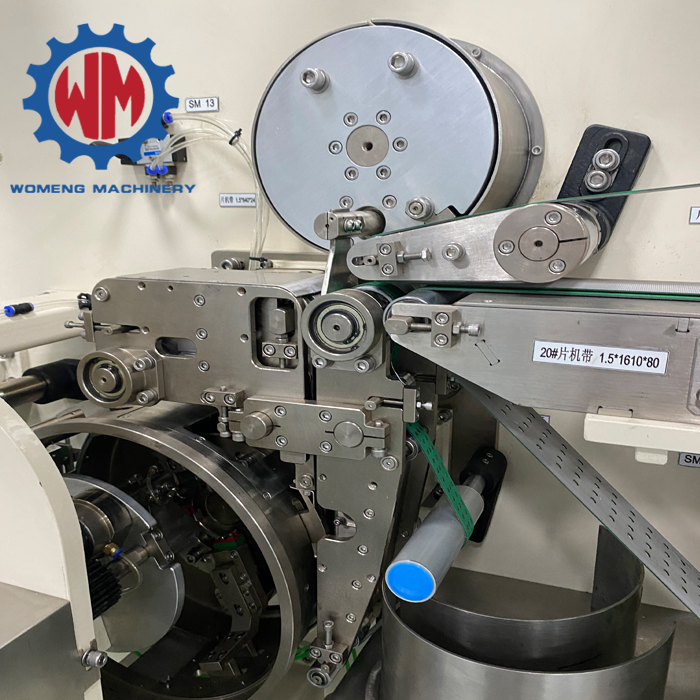

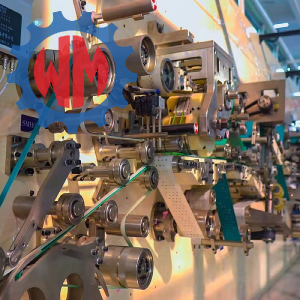

CE Certificated Straight bag Sanitary Napkin Pad Production Line Machine

CE certificated straight bag sanitary napkin pad production line machine

| Subject | Parameter |

| Overall size(L*W*H) | 30M*6M*4M(For reference only) |

| Machine size(L*W*H) | 24m*2.2m*3m, based on the product provided by client |

| Design speed | 800pcs/min |

| Stable speed | 700pcs/min |

| Pass percentage | 98% |

| Work efficiency | 90% |

| Power source | 380V,50HZ(3phase,4lines+ground wire) |

| Machine capacity | 250KW approximately |

| Air pressure | 0.6-0.8Mpa |

| Machine weight | 60T approximately |

| Color | Customized |

Configuration:

1. Product structure:

Up & Down Tissue Fluff core(mix with SAP),ADL,Backsheet,Frontal tape,Topsheet,Leg cuff N.W,Side tape,Waistband.

2. Product size:

230mm-320mm

3. Control system:

PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

4.Tension system:

Up & Down Tissue,ADL,Back sheet,Top sheet,Cuff N.M,are adopt A& B shaft active unwinding by inverter motor.

5.Drive system:

3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer’s requirement

6.Safety system:

It has safety device on the operating side,matched with urgent stop switch,high audio fan uses sound insulation or silencer.

7.Packing way:

Equipped with the stacker at the request of client.

8.Material Corrective System:

Germany BST automatic web guide system(optional)