Full servo sanitary napkin machine pad and wrapped production line machine produce sanitary napkin

Full servo sanitary napkin machine pad and wrapped production line machine produce sanitary napkin

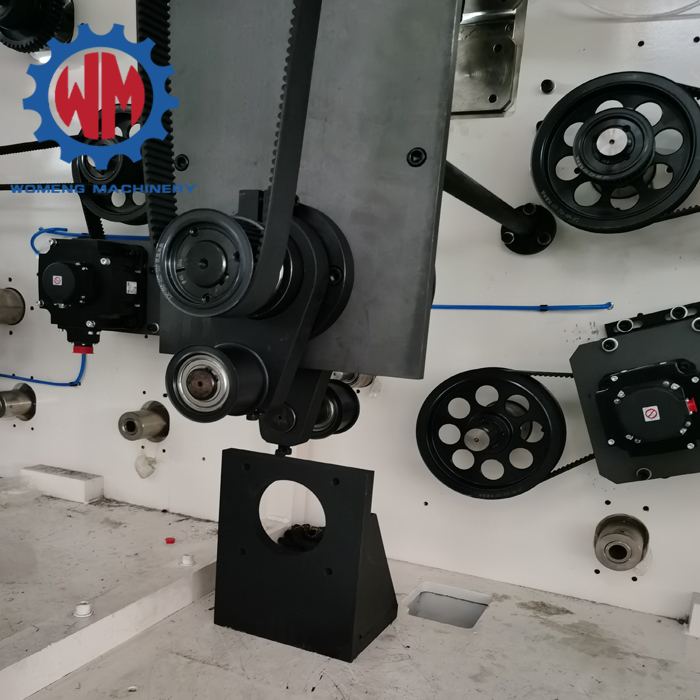

Sanitary Pad Machine Main Features

1. Compact design.Easy operation and maintenance 2. Mould design,allow upgrade machine

3. Low power consumption,high efficiency 4. Servo or inverter drive 5. Human-machine interaction interface 6. Auto record,counproduction data 7. Main raw material auto splicing without stop 8. Frequency converter or servo motor unwinding,auto tension control 9. Automatic web guider unit 10. Automatic quality detection by sensor 11. Auto stop while material break,automatically detect or reject if missing raw materials.

Machine Application

This machine is suitable for manufacture kinds of sanitary napkin shapes with different raw materials. It is widely used to produce the sanitary napkin with wings, sanitary napkin without wings, sanitary napkin with 230mm, 270mm, 320mm, 375mm ultra thin printed or up to buyer, etc.