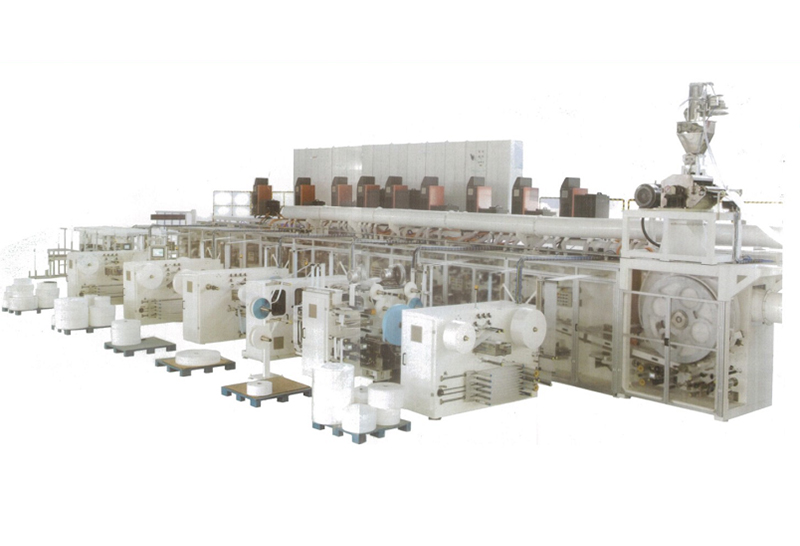

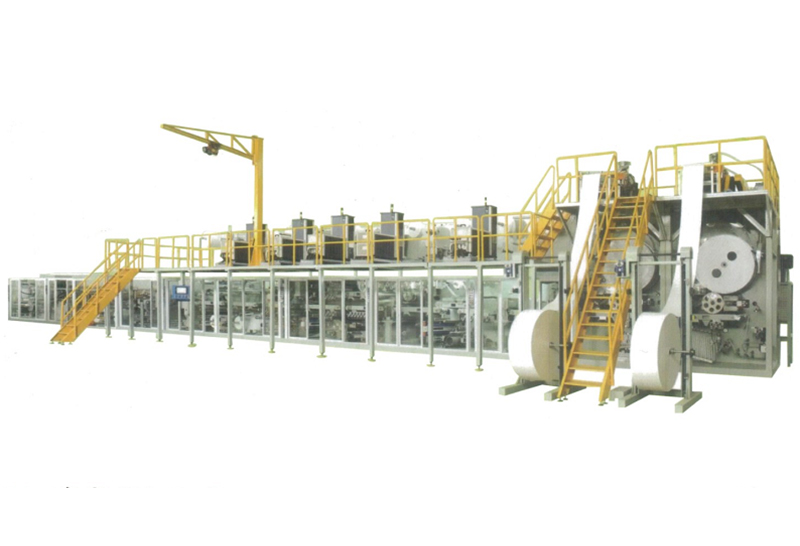

Good quality Adult Diaper - WM-CK300 Full servo Adult diaper Production – Womeng

Good quality Adult Diaper - WM-CK300 Full servo Adult diaper Production – Womeng Detail:

Configuration

Product structure: Leg cuff fabric, to sheet Nw, cotton core (SAP mixed), small S sticker, elastic waistband,frontal tape, back sheet.

Produce size: M:680x450L:800×650 XL:950×760( Customized according to customer requirement)

Control system: PLC programming control, HMl operation, LED digital display graphic digitization control.

Tension system: leg cuffs fabric, top sheet NW, elastic waist, upper & bottom tissue, ADL, back sheet use inverter unwind by A & Bshaft independently.

Drive system: full servo drive, digital size change, ensure run synchronized at full process, The frontal tape adopt servo positioningcutting to ensure pattern consistent with the phase.

Safety system: safety guard installed at the operating side, equipped with emergency stop switch, security identifier. Driven side is equipped with safety pull wire. High audio fan uses sound insulation or silencer.

Packaging system: auto stacker to be defined by customer need (dual push dual exit), the stacking quantity 16-40pcs/ pack adjustable.

Materials corrective system: Adopt international famous brand deviation correction system

Product quality debugging

According to the requirements of the technical contract regulations, interpret the production line process flow, product structure drawing and other related equipment instructions before entering the commissioning; enter the corresponding station (art) on the site, and then the transmission will check the assembly quality (machine inspection standard, flow chart) basis Standards are checked item by item, problems are found, and timely feedback is found, and they participate in research and resolution and formulate solutions.

After entering the machine operation stage, that is, after the belt is adjusted, a second inspection will be carried out, and the machine will be inspected on the parts that cannot be inspected without operation. After the inspection, the inspection situation and problems will be reported to the team and the supervisor, and participate in the research to solve and formulate a treatment plan.

Enter the product trial production stage, and check the material functions such as: broken material detection function, cutting of various tools, material composite, material tightness, glue level control, crusher effect, cotton molding effect, etc. The above content should be different at high and low speeds. Perform tests under conditions and make records. According to the recorded indicators, the team leader and supervisor will verify the results of the machine, and the results will be solved before the customer arrives at the factory for acceptance and finally submitted to the customer for acceptance.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Good quality Adult Diaper - WM-CK300 Full servo Adult diaper Production – Womeng , The product will supply to all over the world, such as: Montpellier, Albania, Madras, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.