Welcome to our websites!

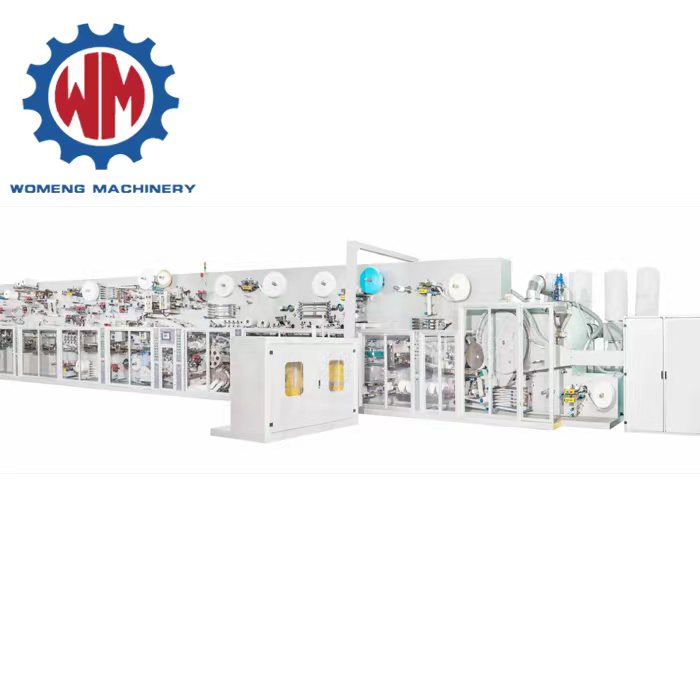

Menstrual Pads Machine Fully Automatic Sanitary Napkin Making Machine

menstrual pads machine fully automatic sanitary napkin making machine

PRODUCT SPECIFICATIONS

|

1

|

Design speed

|

600pcs/min

|

|

2

|

Stable working speed

|

500pcs/min

|

|

3

|

Qualified rate

|

≥ 97%

(exclude the wastage due to the glue applicators and materials splicing joint) |

|

4

|

Efficiency

|

≥ 85%

|

|

5

|

installation capacity

|

≥240KW

|

|

7

|

Electricity

|

380V ±5%、50HZ

|

|

8

|

Wire

|

Three phases four wires 380V/50Hz (ground wire) 3X120mm³+1X50mm³+1X25mm³

|

|

9

|

Air pressure

|

≥0.8Mpa 2.6m³/min

|

|

10

|

Total weight

|

About 78tons

|

|

11

|

Machine size

|

32×8×5 M(L×W×H)

|

|

12

|

Working space

|

38×12×8 M (L×W×H)

|

|

13

|

Machine color

|

Rice white ,can be changed by order

|

|

14

|

Product size

|

S,M,L,XL

|

|

15

|

Containers

|

6X40HQ

|

PRODUCT CONFIGURATION

1. Reasonably solid square steel frame

2. Crusher system

3. Fluff forming system

4. SAP feeding system

5.Tissue, roll diameter φ800mm (air laid paper, roll diameter φ1200mm) supply:

6. Fluff core wrapped by tissue

7. Absorbent paper supplyφ1200mm

8. Absorbent paper short cutting device

9. Fluff core inner cut device 1 set, adopt the frame type tool holder structure to improve the service life of the tool roller

10. The waste at both ends of the core body is sucked and collected

11. Top sheet nonwoven (perforated film) supply, roll diameter φ800mm

12. ADL (blue chip) supply,φ600mm

13. Bottom film supply, roll diameterφ600mm

14. Bottom nonwoven supply, roll diameterφ800mm

15. Two sides nonwoven supply (3-piece nonwoven)

16. Channel pressing roller device

17. Composite of two sides nonwoven and top sheet nonwoven

18. Central release paper device, roll diameter: φ500mm

19. Central release paper cutter

20. Forming cutter

21. Wastage recycling unit

22. Product 180-degree overturn

23. Wing release paper adding unit, φ500mm

24. Wing release paper cutter

25. Product 90 degree turn round

26. Packing film supply, roll diameter φ800mm

27. packaging film and product adhesive roller

28. Second grade warp

29. Product quick easy package exhaust

30. Quick easy tape adding unit

31. Quick easy package sealing

32. Quick easy package cutting unit

33. Reject exist, auto rejecting (air blow)

34. Two ways output device

35. Reserve stacker and auto bagger machine

2. Crusher system

3. Fluff forming system

4. SAP feeding system

5.Tissue, roll diameter φ800mm (air laid paper, roll diameter φ1200mm) supply:

6. Fluff core wrapped by tissue

7. Absorbent paper supplyφ1200mm

8. Absorbent paper short cutting device

9. Fluff core inner cut device 1 set, adopt the frame type tool holder structure to improve the service life of the tool roller

10. The waste at both ends of the core body is sucked and collected

11. Top sheet nonwoven (perforated film) supply, roll diameter φ800mm

12. ADL (blue chip) supply,φ600mm

13. Bottom film supply, roll diameterφ600mm

14. Bottom nonwoven supply, roll diameterφ800mm

15. Two sides nonwoven supply (3-piece nonwoven)

16. Channel pressing roller device

17. Composite of two sides nonwoven and top sheet nonwoven

18. Central release paper device, roll diameter: φ500mm

19. Central release paper cutter

20. Forming cutter

21. Wastage recycling unit

22. Product 180-degree overturn

23. Wing release paper adding unit, φ500mm

24. Wing release paper cutter

25. Product 90 degree turn round

26. Packing film supply, roll diameter φ800mm

27. packaging film and product adhesive roller

28. Second grade warp

29. Product quick easy package exhaust

30. Quick easy tape adding unit

31. Quick easy package sealing

32. Quick easy package cutting unit

33. Reject exist, auto rejecting (air blow)

34. Two ways output device

35. Reserve stacker and auto bagger machine

Write your message here and send it to us