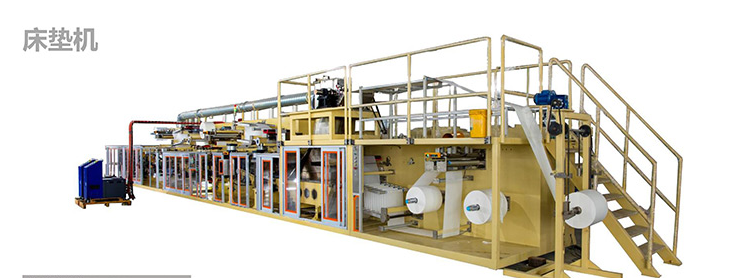

OEM manufacturer Diaper Machine Automatic - Dry Disposable Urine Puppy Pads Pet Training Machine Production Line – Womeng

OEM manufacturer Diaper Machine Automatic - Dry Disposable Urine Puppy Pads Pet Training Machine Production Line – Womeng Detail:

|

1

|

Design speed

|

240meters/min

|

|

2

|

Stable running speed

|

180 meters/min (3&5 layers ,treated pulp, fluff GSM 40-80/M2)

|

|

3

|

Qualified rate

|

≥ 98%

(exclude the wastage due to the glue applicators and materials splicing joint) |

|

4

|

Efficiency

|

≥ 85%

|

|

5

|

Installation capacity

|

Main machine:200KW.

|

|

6

|

Electricity

|

Three phases four wires 380V/50Hz (ground wire)

|

|

7

|

Wire

|

3×95MM2+1×25MM2+1×16MM2

|

|

8

|

Lowest pressure

|

≥0.6mpa , 2.6m3/min

|

|

9

|

Total weight

|

70 tons

|

|

12

|

Machine size

|

23×7.5×2.8 M(L×W×H)

|

|

13

|

Working space

|

26×10×6 M(L×W×H)

|

|

14

|

Products

|

Three layer products :inside fluff core discontinuous forming /

Five layer products : inside fluff core continuous forming |

|

15

|

Machine color

|

RAL1013, or other color to be customized

|

|

16

|

Product size

|

5 layers pads: Width: 450-600mm adjustable,

length is 450-1500mm adjustable 3 layers pads: Width: 450-600mm to be customized, length is 450-1500mm to be customized |

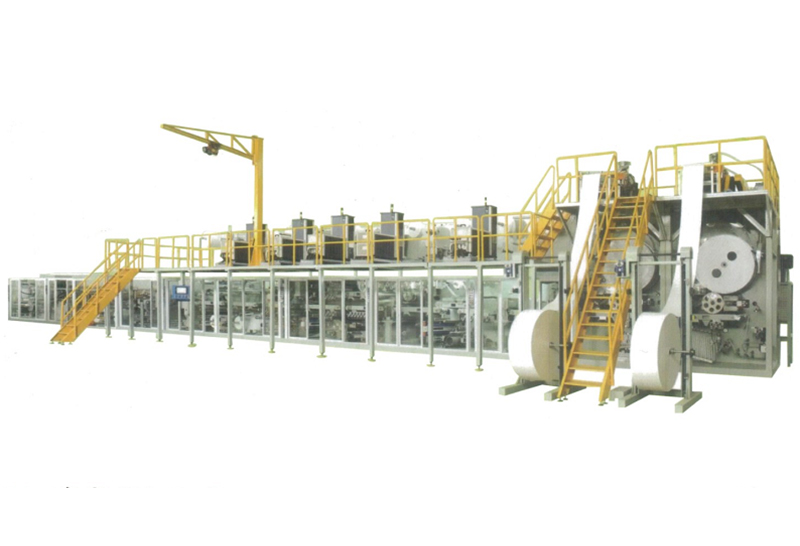

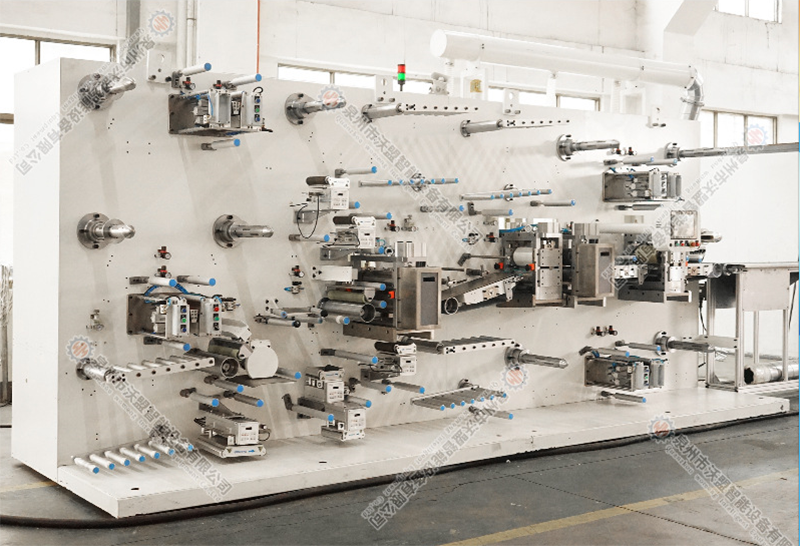

1. Reasonably solid square steel frame: Panel 25mm thick, solid cage with 60 * 60mm square steel, the base frame with square tube 120mm × 120mm, The thickness of the bottom plate is 18mm.

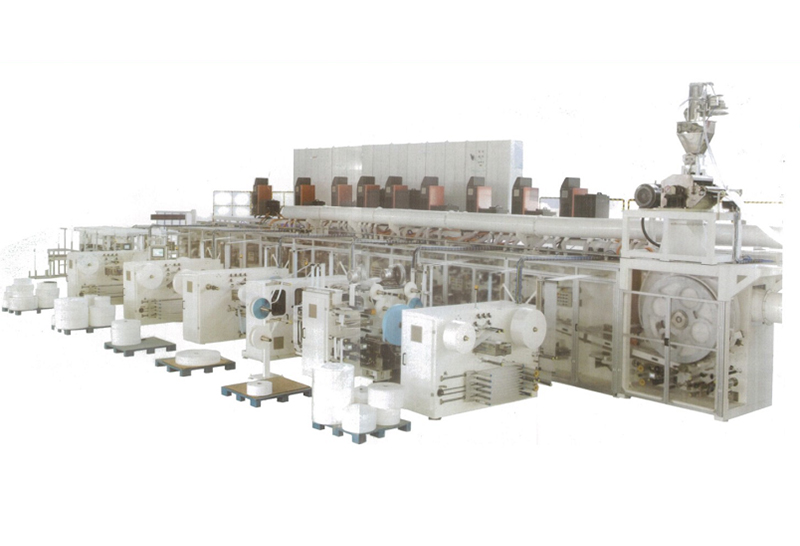

2. Crusher system:

3. Fluff core forming system:

5 layers under pads :

1)Single forming drum, the diameter of the forming drum is about 1200mm, the cellulose is evenly distributed, and the size of

forming drum molds are customized according to demand.

3 layers under pads:

* Single forming drum with continuous fluff core forming, the diameter of the forming drum is about 1200mm, the cellulose is evenly distributed, and the size of forming drum molds are customized according to demand.

5. SAP feeding system:

6. Bottom tissue feeding, roll diameter φ800mm

7. Upper tissue feeding, roll diameter φ800mm

8. Fluff core and upper/bottom tissue lamination

9. Fluff core flat compact roller

10. Fluff core rhombus shape embossing unit

11. Fluff core cutting device

12. Top sheet hydrophilic non woven feeding, roll diameter φ800mm

13. Back sheet PE film feeding, roll diameter φ600mm

14. 2 sides release paper feeding, roll diameter φ450mm

15. Release paper glued on the bottom film

16. Y-shape roller

17. Finished product horizontal folding unit

18. Final cut unit

19. Product vertical 2-folding or 3-folding, frequency control

20. Blow type auto rejection exit

21. Output wheel, the output platform is 2.5meters.

22. Conveying and driving system * Adopt servo motors +frequency convertor +three-axis for transmission controlling, main raw materials unwinding driven by

frequency control, to guarantee the precision and stability of the machine in high speed, and can realize not change any transmission parts to change the product’s size, can directly set on PLC, easy to operate and maintain

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for OEM manufacturer Diaper Machine Automatic - Dry Disposable Urine Puppy Pads Pet Training Machine Production Line – Womeng , The product will supply to all over the world, such as: Brunei, France, Las Vegas, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we've been likely to be pleased to serve you.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.