WM-DHY500 Full servo big ring waist baby diaper Production

Configuration

Product structure; upper & lower tissue, cotton core (mix with SAP),ADL, PE film, frontal tape, cover sheet hydrophilic non-woven, leg cuff hydrophobic non-woven, side small " s' shaped waist sticker, online molding elastic waistline,

Produce size:S:390x320M:450x320L:500x320XL:525x320

Control system: PLC programming control, HMI operation, LED digital display graphic digitization control

Tension system: tension unwinding equipped, constant control with buffer system, automatic Web guide system. The unwinding system ensure materials stable working at full speed splice,minimize the impact on materials tension force, to reduce downtimes.

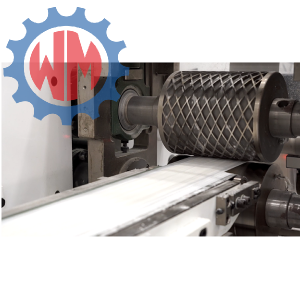

Drive system: full servo drive, digital size change, ensure run synchronized at full position cutting to ensure pattern is in phase.

Safety system: safety guard installed at the operating sign, with security identifier, emergency stop switch at per segment, Driven sideis equipped with the radiator system and safety pull wire.

Packaging system: according to customer requirements with palletizer machine (double push double exit)adjustable.

Materials corrective system: Adopt international famous brand deviation correction system

our service

We have a comprehensive and thoughtful one-stop service process, including pre-sales, in-sales, and after-sales.

Pre-sale

Communicate online and consult actual needs.

Visit customers and communicate face to face.

Understand and analyze product raw materials and equipment configuration requirements.

Communicate the solution and finalize the configuration plan.

Determine the plan price and service cycle.

On sale

Provide a schedule of equipment production schedule.

Provide customers with technical personnel entering the factory for learning, communication and training.

Debug the equipment to the best condition for acceptance and delivery.

After sale

Our equipment has a full-time after-sales team to follow up from the beginning of the shipment to ensure the installation progress and the accuracy of the quantity of goods.

We have a one-to-one after-sales service group with customers, including the participation of technical, production and management personnel from both parties.

We also maintain irregular customer visits, conduct on-site guidance, and handle production accidents in an embryonic state.

Our service is not the best, only better! To escort customers!